Visual Die Protection is a system that utilizes cameras and intelligent software to monitor the production process. This system detects unexpected causes of trouble and halts the press, allowing you to prevent die damage and the ensuing costs. For example, if a foreign body, even just a scrap of sheet metal, is detected in the die, the press will stop automatically so that there is no chance of the object being pressed into active surfaces of the die, let alone the die breakage. By integrating additional cameras, the system can also be expanded to monitor the scrap chutes and other areas of the machine, for example. This means that Visual Die Protection delivers increased process reliability for your production operations. Especially where just-in-time supply chains with small inventories are used, you can safeguard your ability to supply while also increasing the uptime of your systems.

Cameras with an eye for detail

Up to eight monitoring functions can be configured to achieve greater process stability in production. By monitoring different segments or process steps, Visual Die Protection is able to cover a number of problem sources and thereby prevent unanticipated malfunctions. Not only does this reduce your probability of downtime, it also ensures safe operation of your systems.

The monitoring functions included range from part position verification, foreign body detection, and in-process checks to the targeted monitoring of critical die functions with increased precision.

Flyer | Visual Die Protection

pdf, 1 MByte

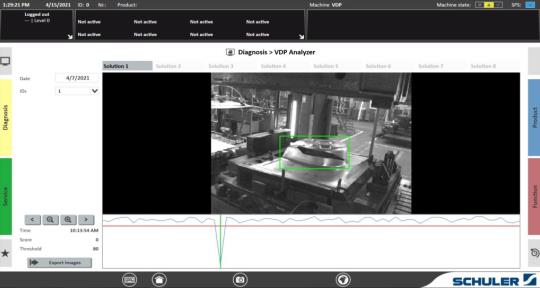

More insights with the VDP Analyzer

You know the situation: a disturbance occurred during the night shift. When trying to trace the disruption and its cause, you reach your limits. The VDP Analyzer provides a remedy: it offers convenient access to historical image series and data for detailed analysis of your production process, thus contributing to the continuous improvement of your processes and error prevention.

Visual Die Protection safeguards your dies

We need your consent to load content.

In order to show videos we use the services of third-party providers. These providers can collect data about your activities. Further details can be found under “Learn more”.

Success story

We need your consent to load content.

In order to show videos we use the services of third-party providers. These providers can collect data about your activities. Further details can be found under “Learn more”.

Convincing system performance in the field

There’s no question that Schuler stands behind its products. It’s also something that customers and experts in the industry can attest to. Household appliance manufacturer Neff, based in the town of Bretten in Germany’s Baden region, purchased the die monitoring system and has reported a positive experience so far. See for yourself:

Microsoft Intelligent Manufacturing Award

“Innovate. Transform. Complete.” Under this motto, more than 60 industrial companies have submitted their application for the Microsoft Intelligent Manufacturing Award 2020. With Visual Die Protection, Schuler has made it to the finalists.

Your benefits

Here are your benefits with Visual Die Protection:

Benefits and features

- Prevention of costly die damage and uninterrupted ability to supply

- Increased process stability

- Increase in system uptime through reduction of unanticipated malfunctions

- Process monitoring and image analysis provide insight into cause behind malfunctions and enable preventative maintenance

- Lower costs for die repairs

- More transparency in your production*

- Reduction of failure rates*

- Consistent documentation thanks to image export*

- Convenient access even from the office*

*optional with VDP Analyzer

Operation and convenience:

- New dies can be taught into system quickly and easily thanks to intuitive operation

- On-site assistance with initial setup

- No need to reconfigure system when dies are used again. Existing data records are simply reused or modified.

Visual Die Protection can be retrofitted to a wide variety of systems - both Schuler presses and presses from other manufacturers. Convince yourself and make an appointment with us for a test day in your press shop. With our mobile image processing system, we will carry out a feasibility analysis for your specific application directly on your plant.

Ahmet Cansever

Technical Sales Engineer Digital Solutions

Ernst Schwoshuber

Head of Service Sales Germany