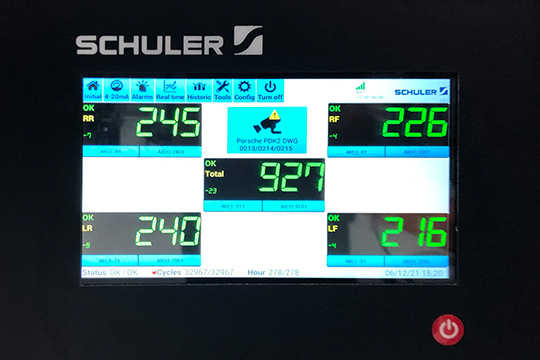

The Smart Monitoring System is a stand-alone system for press force, vibration and temperature measurement with a separate operating panel on the press and a full online display. This allows you to evaluate all measured values and production data.

This solution can be easily retrofitted to all older Schuler and third-party system that either have no press force sensors system or one that cannot be detected. This allows you to establish comprehensive and detailed measurements as well as monitoring of your production data. Alternatively, if you already have a newer system fully equipped with sensors, Cloud Solutions may be of interest to you. If you only need data for your third-party system, the Machine Data Link may be of interest to you.

By connecting the system via the die control unit and die safety device, stop signals can also be output virtually in real time and the system can be stopped in the event of press force deviations.

All measured values are transmitted to the cloud via an edge device and displayed there in a user-friendly manner. You can access the measured values from any terminal device.

Integrated operating panel

The Smart Monitoring System is particularly suitable for monitoring older system and/or problem dies. Up to twelve sensors (acceleration, temperature, strain gauge) can be individually integrated and their measured values visualized. Even after installation, the sensors themselves and their positions can still be adjusted.

Thanks to these systems, you are able to optimize your processes. They can identify deviations through individual measurements and get to the bottom of problems. As you can detect deviations at an early stage and initiate countermeasures in good time, you prevent unplanned downtimes and avoid damage to your system.

Everything in view – available online 24/7, wherever you are

With the Smart Monitoring System, up to twelve sensors can be individually attached to your system. An edge device installed on the system transmits the data from the sensors to the cloud – so this data can then be viewed on your smart devices anytime, anywhere.

The measured values and trend curves are evaluated and displayed in relation to the die. FFT analyses of vibration measurements are also possible online. This provides you with reliable production and machine data in a simple and fast manner. Use this data to optimize problem areas and quickly analyze errors.

We need your consent to load content.

In order to show videos we use the services of third-party providers. These providers can collect data about your activities. Further details can be found under “Learn more”.

Your advantages

Convince yourself of the advantages of the Smart Monitoring System:

- Completely stand-alone system

- Can be installed on any older Schuler press and third-party presses

- Connection via die control unit and die safety device

- Online evaluations

- Results available via smart devices – anytime, anywhere

- System shutdown possible in case of press force deviations

- Individual vibration and temperature analyses possible

- Condition monitoring can be implemented for the system drive by means of vibration and temperature monitoring

- Further solutions are possible from the Digital Suite

- Absolute security against hacker attacks because the system is not connected to the system control unit

Philip Föhr

Key Account Manager Industry / Schuler Service

location_on Schussenstr. 11, 88250 Weingarten phone +49 751 401-2951 mail_outline E-Mail

Martin Schempp

Product Management Stamping & Cutting / Schuler Service

location_on Schuler-Platz 1, 73033 Göppingen phone +49 7161 66-7775 mail_outline E-Mail