Planning on moving your equipment into the world of Industry 4.0? Looking to do so as a way to improve operating performance, for example by lowering production costs and making processes more efficient? Want to leverage this to ensure the growth, competitiveness and future viability of your company? With a number of specially developed applications, Schuler has opened the door to a simple, uncomplicated path to the digital future. These applications allow you to monitor production, process and/or status data, to access this data from a desktop computer or smart device, and to have the data presented in a plain and understandable format. This gives you the capability of identifying areas of improvement in your production process in even less time.

Choose the applications you’re interested in and keep reading to find out more.

Secure connections

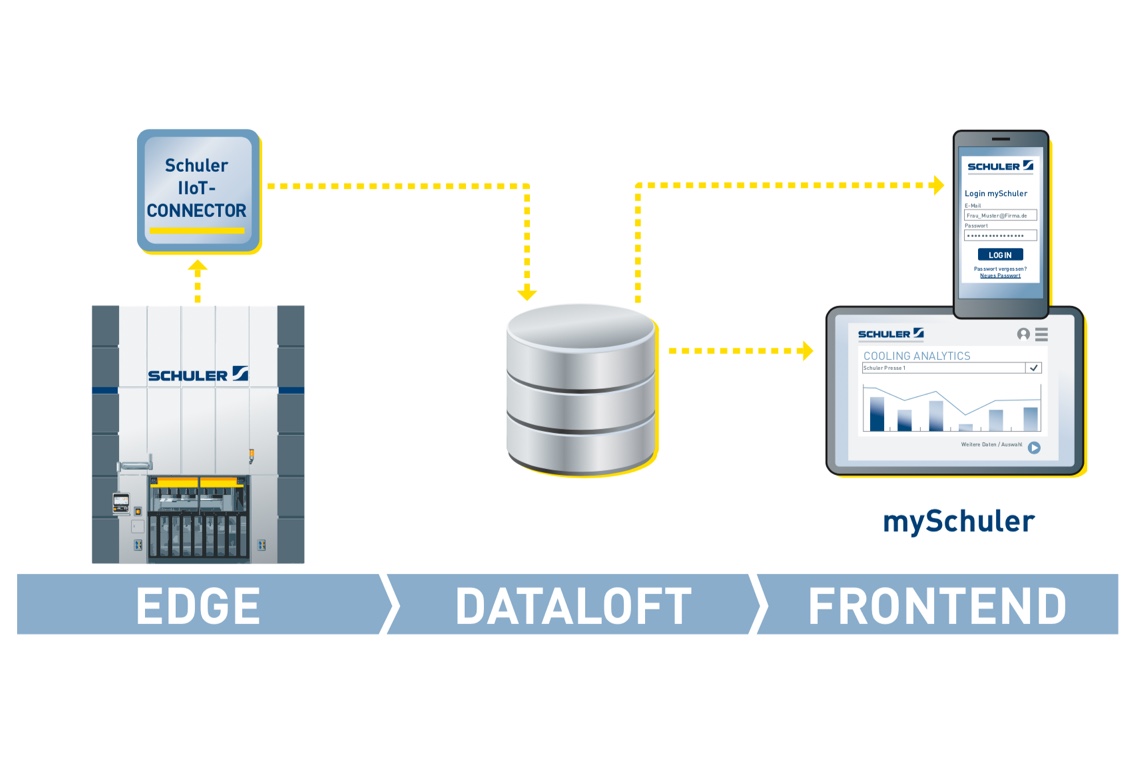

The fundamental requirement for using the applications is getting your machine connected to the internet. This is made possible by the right hardware, which can also be retrofitted onto your machine. This hardware allows the machine to communicate with the Schuler DataLoft, our core computing center for managing, processing, and visualizing machine- and process-related data. It also gives you access to your data through the mySchuler portal. In addition to data, you can also easily find documents such as operating instructions, maintenance instructions, and more using the portal. You remain the sole owner of your data. For maximum security, the data is transmitted to the Schuler DataLoft over a one-way connection, i.e., on a fully separate channel from your system's remote service connection.

Your benefits

See the advantages of the Press Force Monitor for yourself

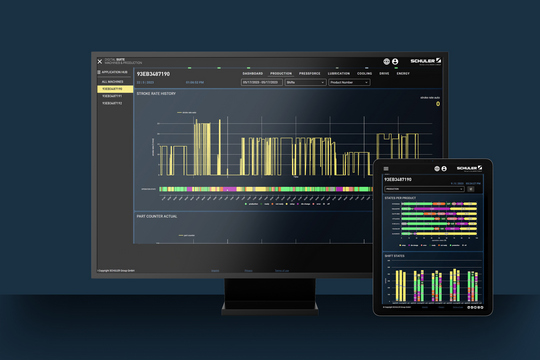

- Current and historical process data (stroke rates, peak press force, infeed/outfeed press force ratio) are available whenever you need them.

- Data can be accessed from any smart device.

- Comparison of die-specific process data over periods of time and production shifts.

- Identification of incorrectly positioned dies in the direction of flow.

- Detection of improperly set press forces specific to each die.

- Early detection of die-specific discrepancies in the press force distribution, which allows the detection of emerging die damage.

- Use of die-specific historical data (e.g., number of strokes with the die) to plan die overhauls.

Dr. Stefanie Apprich

Product Owner Cloud Services und Digital Suite

Uwe Rosenauer

Key Account Manager

Weitere verfügbare Applikationen

Production Monitor

Keep track of everything: The Production Monitor provides all of the information you need to monitor and optimize your system productivity.

Find out more

Energy Monitor

The Energy Monitor gives you transparency about the energy status of your systems and thus sustainably reduces energy costs in production.

Find out more

Cooling Analytics

Keeping things cool: Your equipment can run as long as the cooling system is in good shape. End-to-end monitoring of the cooling circuits therefore ensures high system uptime.

Find out more

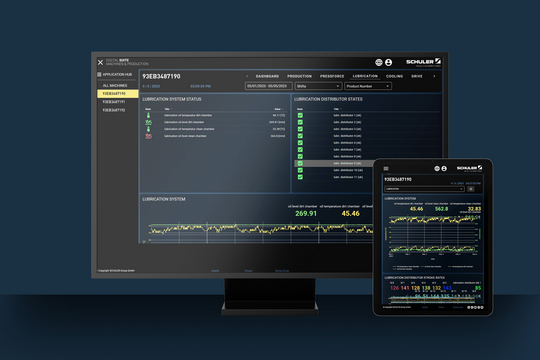

Lubrication Analytics

Plan oil changes and filter replacements when they’re actually needed. To keep everything moving smoothly.

Find out more

Drive Analytics

Damage to the drive or converter can cause costs to pile up before you know it. To keep this from happening, Drive Analytics makes sure that you’ve got a handle on things at all times.

Find out more