THE EFFORTLESS WAY TO SMART QUALITY CONTROL

Reliable control with camera-based Visual Quality Inspection (VQI): The system detects defective components already during production and separates them out. The system uses error-free parts as templates, which are scanned by the system with just a small number of mouse clicks. This eliminates the need for time-consuming marking of part contours and annotation of defects. This intuitive operation makes VQI a flexible add-on for production systems of all manufacturers and types that can be used variably. This ensures that only defect-free components are delivered to the customer - which means no complaints, saves costs and increases customer satisfaction.

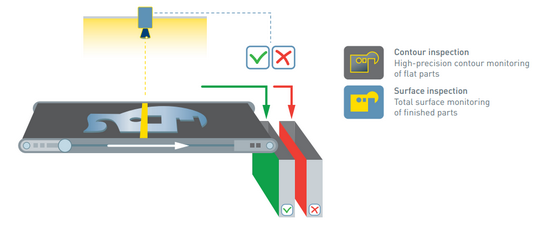

CAMERA-BASED INTERMEDIATE AND FINAL INSPECTION

Visual Quality Inspection can be used for contour monitoring of flat parts as well as for inspection of finished parts. Depending on the component size, defect characteristics and environmental conditions, we design the system optimally to meet your requirements. Thus, no defect remains hidden.

The production process does not have to be stopped to scan the components. Visual Quality Inspection thus ensures maximum quality assurance while maintaining productivity.

Flyer | Visual Quality Inspection

pdf, 318 KByte

MORE INSIGHTS WITH THE ANALYZER

The Analyzer provides convenient access to historical image series and data for detailed analysis of your production process. It thus ensures continuous traceable documentation of your component quality.

Your benefits

- Automation of quality control to increase reliability of error detection

- Reduction of complaint, sorting and scrap costs

- Improvement of customer relation

- Process independence: one system for a wide range of applications

- Simple and fast way to visual quality control

- Low training effort for operators

- System training only with OK parts and without time-consuming marking of part contours or annotation of defects

- Quick and easy setup for new parts and reuse existing product data sets

- Simple system integration

- Flexible system setup, tailored to your need

- Continuous traceability*

- Convenient access even from an office workstation*

- Consistent documentation thanks to image export*

*More insights with the Analyzer

Visual Quality Inspection can be retrofitted to a wide variety of systems - both Schuler presses and presses from other manufacturers. Send us your parts and we will perform a feasibility analysis for your specific application. You get to know from us which defect characteristics and size can be detected in a process-safe way.

Ahmet Cansever

Technical Sales Engineer Digital Solutions

Ernst Schwoshuber

Head of Service Sales Germany